How ISO 9001 Can Help in Finding Reliable Bag Factories

Quality certification matters—especially when choosing a manufacturing partner for custom leather bags. One standard that consistently stands out globally is ISO 9001. Brands that understand ISO 9001’s purpose and implementation can make more informed decisions, reduce risk, and build long-term partnerships with reliable bag factories.

In this article, we explain what ISO 9001 is, how it shapes manufacturing processes, and why it matters when selecting a dependable leather bag manufacturer.

1. What Is ISO 9001 Certification?

ISO 9001 is an internationally recognized standard for Quality Management Systems (QMS). Issued by the International Organization for Standardization (ISO), it provides a framework that ensures consistent quality in products and services.

At its core, ISO 9001 helps organizations:

-

Standardize processes

-

Track performance and quality metrics

-

Improve customer satisfaction

-

Continually enhance operational systems

For manufacturers, this certification demonstrates a commitment to structure, documentation, and repeatable quality. It is not specific to leather goods but applies to how a company manages all aspects of production and quality control.

Advantages of ISO 9001 certification include:

-

Third-party validation of quality systems

-

Better internal communication and performance monitoring

-

Greater transparency between factory and brand

For brands interested in long-term suppliers rather than quick, disposable partners, ISO 9001 is often a minimum requirement.

2. How ISO 9001 Sets Seven Key Stages in Bag Manufacturing

ISO 9001 doesn’t tell factories exactly how to make leather bags, but it does define stages of a structured quality process. Many high-performing bag factories adopt this framework to manage complex production flows.

Here are seven key stages that ISO 9001 encourages in custom leather bag manufacturing:

1. Requirements Analysis

Clear documentation of materials, function, tolerances, and brand expectations.

ISO 9001 emphasizes capturing accurate customer requirements before production begins.

2. Design and Prototyping

Structured sampling and prototype approval phases ensure the bag design meets functional and aesthetic goals before bulk production.

3. Material Sourcing Quality Checks

Factories implement criteria to evaluate incoming leather, hardware, and accessories, ensuring consistent batch-to-batch quality.

4. Process Planning & Standardization

Documented workflows guide cutting, stitching, assembly, and finishing. This reduces variance and supports predictable outcomes.

5. In-Process Quality Control

Real-time checks at key points (stitch time, tension, alignment, hardware installation) reduce defects and rework.

6. Final Inspection & Release

Before shipment, products go through final evaluation based on approved samples and documented criteria.

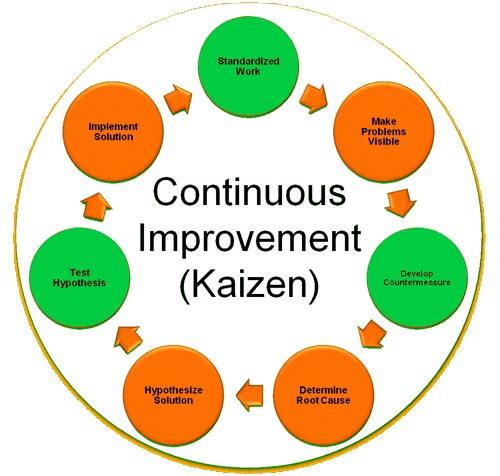

7. Feedback & Continuous Improvement

ISO 9001 mandates corrective action systems, enabling factories to learn from defects and improve future production cycles.

By codifying these stages, certified factories can proactively manage quality risks and deliver consistent outcomes at scale.

3. Why ISO 9001 Helps Brands Find Reliable Leather Bag Manufacturers

For brands seeking dependable partners, ISO 9001 certification offers concrete benefits beyond a printed certificate.

● Objective Assurance of Process Discipline

Instead of relying solely on brand claims or sales pitches, buyers can point to ISO 9001 as evidence that the factory maintains documented procedures and structured quality control systems.

● Reduced Production Risk

A certified factory is more likely to:

-

Follow systematic sampling policies

-

Track quality metrics

-

Respond to non-conformities

-

Avoid surprises during mass production

This reliability directly reduces costly delays, rework, and product failures.

● Easier Supplier Evaluation

When comparing multiple bag factories, ISO 9001 certification serves as a baseline criterion. Buyers can focus on value-added features (design support, MOQ flexibility, lead times) once quality systems are confirmed.

● Better Communication and Transparency

ISO 9001 encourages documented approvals, change logs, and traceable decisions—skills that improve communication clarity between brands and manufacturers.

In short, ISO 9001 helps brands filter serious manufacturers from those operating with ad-hoc processes.

Final Thoughts

ISO 9001 doesn’t guarantee that every bag will be perfect—but it dramatically increases the likelihood of consistent quality. For brands launching custom leather bag collections, certification offers a measurable way to assess factory reliability.

Whether you’re a new label or an established brand, prioritizing ISO 9001-certified manufacturers helps secure smoother sampling, tighter quality control, and more predictable production outcomes for your custom bag orders.