The Truth Behind Custom Bag Companies: How to Achieve Quality and Personalization

In the evolving world of fashion and branding, custom bag manufacturing has emerged as a pivotal service for both startups and established businesses. From personalized totes to branded backpacks, custom bags offer a unique opportunity for companies to express their identity and elevate customer experiences. However, navigating the landscape of custom bag suppliers requires a deeper understanding of how quality and personalization are truly achieved.

Understanding the Core of Custom Bag Manufacturing

Custom bag companies serve a wide range of clients, including fashion entrepreneurs, promotional product agencies, private label brands, and creative designers. These clients often seek more than just a functional bag—they want a product that reflects their brand values, aesthetics, and target audience.

Unlike mass-produced options, custom bag manufacturing allows for the selection of materials, design features, and branding elements, offering a fully tailored product. This process typically includes decisions on:

-

Material types (e.g., genuine leather, PU, canvas, nylon)

-

Structure and dimensions (such as depth, handle drop, and compartments)

-

Hardware finishes (metal zippers, custom pulls, magnetic closures)

-

Branding options (embossing, embroidery, screen printing, metal logos)

A reliable custom bag manufacturer will offer guidance throughout this decision-making process to ensure the final product meets both aesthetic and functional goals.

Low MOQ and Flexible Production Options

One of the most attractive features of many custom bag suppliers is their ability to accommodate lower minimum order quantities (MOQ). This is particularly beneficial for startups or boutique brands testing the market or launching limited collections. Depending on the manufacturer and material type, MOQ can range from as low as 50 pieces per color for leather products to several hundred pieces for fabric-based styles.

Additionally, experienced manufacturers often offer both domestic and overseas production options, providing flexibility in terms of lead time, cost, and craftsmanship preferences.

The Customization Process: From Sketch to Final Product

The journey from concept to final product begins with a clear vision. Most custom manufacturers will start with either a design sketch or reference sample provided by the client. They’ll then translate that idea into a technical drawing or prototype.

The stages typically include:

-

Consultation: Discuss your brand goals, materials, and budget.

-

Sampling: A physical sample is created, often taking 10–18 days depending on complexity.

-

Revisions: Based on feedback, minor adjustments may be made.

-

Mass Production: Once the sample is approved, bulk production begins—usually requiring 30–45 days.

Throughout this process, clear communication with the manufacturer is essential to avoid delays and ensure alignment on quality expectations.

Logo Placement and Branding Impact

Custom bag companies offer various ways to add logos, depending on the desired visibility and product type. Common logo applications include:

-

Debossed or embossed leather patches

-

Woven or printed fabric labels

-

Silkscreen printing or embroidery

-

Metal logo plates

The placement of the logo—whether subtly inside the bag or prominently on the exterior—can greatly influence a customer’s perception of your brand. Therefore, it’s important to consider how your branding aligns with your overall market strategy.

Turnaround Time and Shipping Expectations

Delivery timelines vary based on factors such as order quantity, design complexity, and production location. For most international manufacturers, expect:

-

Sample time: 12–18 days

-

Bulk production: 30–45 days after sample approval

-

Shipping time: An additional 7–30 days depending on shipping method and location

Reliable manufacturers will keep you informed throughout the process and help you plan ahead—particularly if you’re preparing for a seasonal launch or a marketing event.

Choosing the Right Manufacturer: What to Look For

When evaluating a custom bag supplier, consider the following:

-

Experience in OEM/ODM production

-

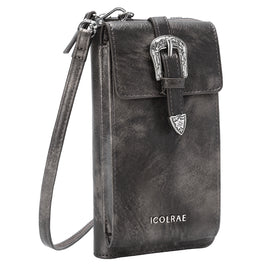

Portfolio showcasing a range of bag types

-

In-house production vs. outsourcing

-

Transparency in pricing, MOQ, and timelines

-

Willingness to collaborate on custom design requests

-

Strong client service and communication

A great manufacturer isn’t just a production facility—they’re a partner in bringing your brand vision to life.

Why HerminFashion Is a Trusted Partner for Custom Bags

Among the leading OEM/ODM manufacturers in China, HerminFashion has built a reputation for helping global brands—especially small and medium-sized businesses—realize their bag design dreams. Located in Guangzhou, HerminFashion operates one of the region’s most modern bag manufacturing facilities:

-

Factory size: 4,000 square meters

-

Monthly capacity: Over 75,000 bags

-

MOQ for leather bags: 50 pcs per color / 100 pcs per style

-

Sample turnaround: 12–18 days

-

Production time: 30–45 days post-sample approval

Whether you’re launching a new line or need reliable production for an established design, HerminFashion provides both expertise and flexibility. They also offer an in-stock wholesale collection for lower-MOQ retail needs.

Interested in custom bags for your brand? Reach out to HerminFashion today to discuss your ideas and receive expert guidance from concept to final delivery.