Why Do We Need to Sample Bags Before Mass-Producing Custom Bags?

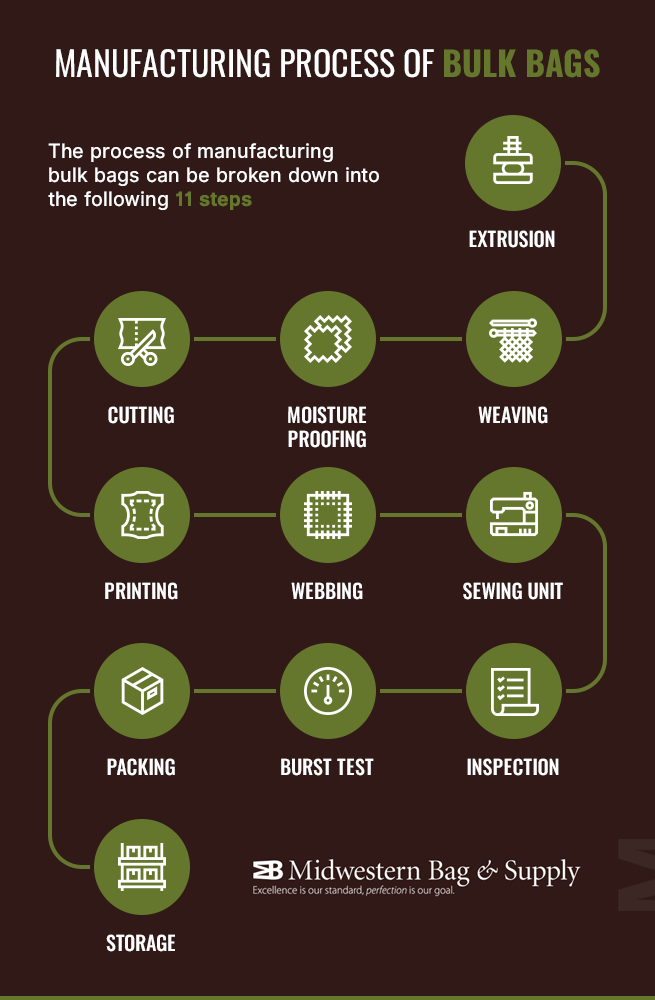

In custom bag manufacturing, sampling is not an optional step—it is a critical quality and risk-control process. For brands placing bulk orders, skipping sampling may seem like a shortcut, but it often leads to costly mistakes, delays, and unmet expectations.

From a factory perspective, sampling bridges the gap between design intent and mass production reality. Below, we explain why sampling is essential and how it protects both brands and manufacturers throughout the custom bag production process.

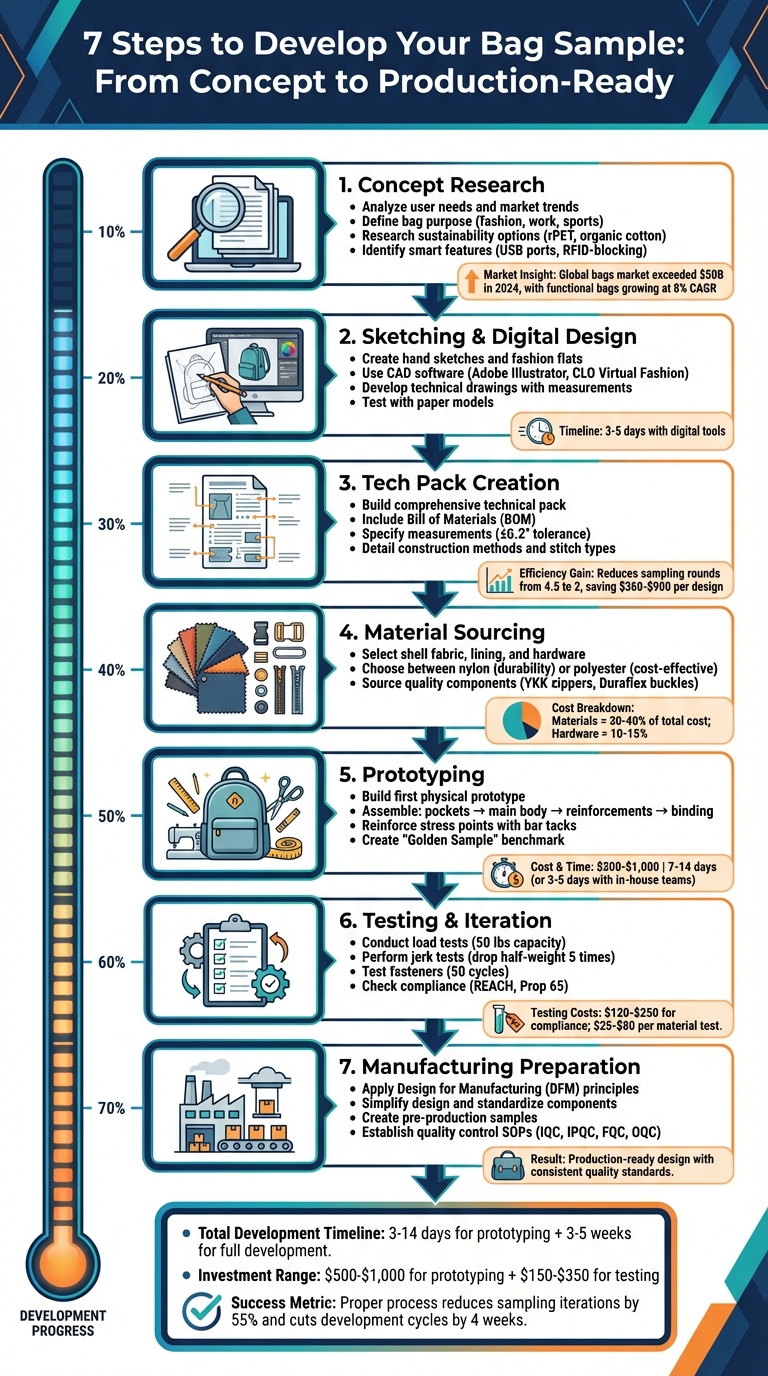

1. Sampling Timeline: Setting the Right Expectations Early

Sampling establishes a clear production timeline before mass manufacturing begins.

A typical sampling schedule includes:

-

Material sourcing and confirmation

-

Prototype construction

-

Functional and visual adjustments

-

Final sample approval

This phase allows both parties to confirm what can realistically be produced within a given timeframe. Without sampling, brands often underestimate lead times, while factories face pressure to meet unrealistic deadlines.

Key benefit: Sampling aligns delivery expectations and reduces last-minute production bottlenecks.

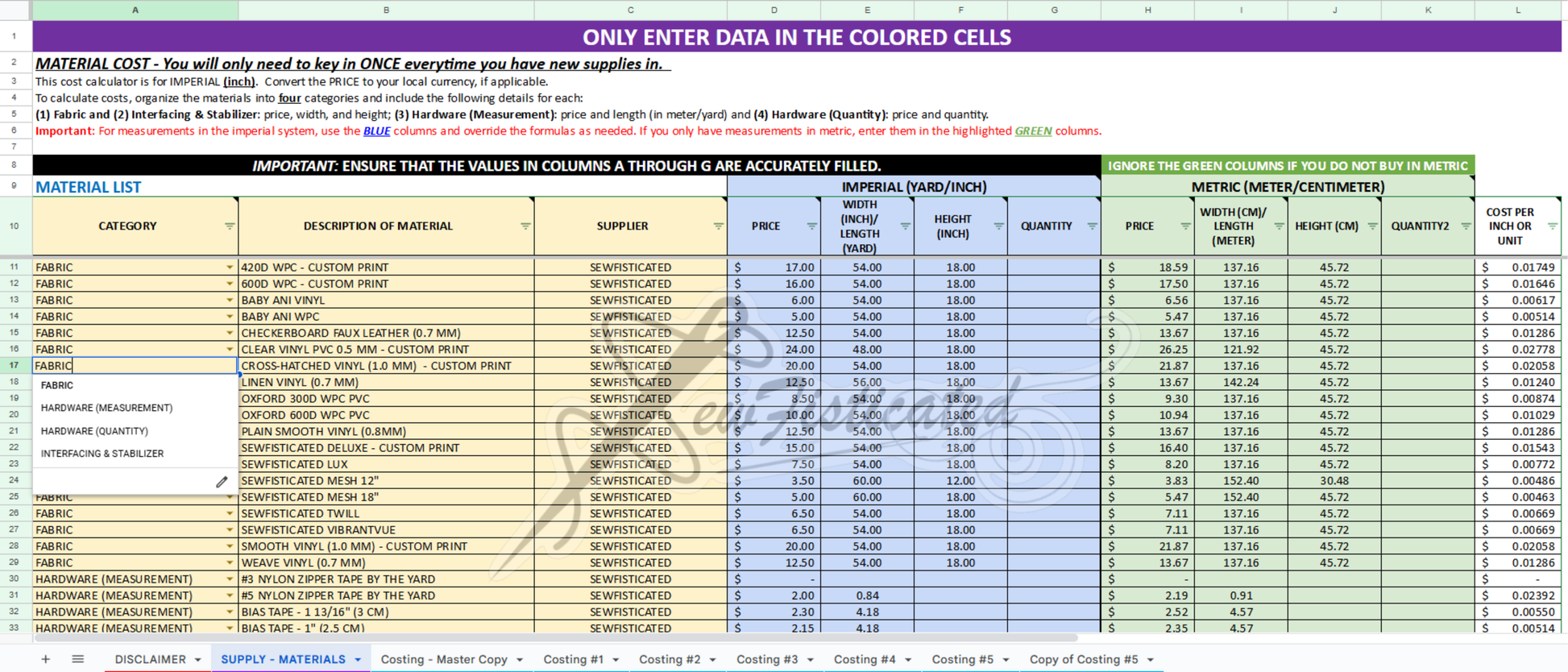

2. Sampling Cost Calculation: A Small Investment That Prevents Big Losses

Sampling involves upfront costs such as:

-

Materials (leather, PU, hardware, lining)

-

Labor and craftsmanship

-

Pattern making and tooling

While sampling does require an initial budget, it provides early cost transparency. It allows brands to evaluate:

-

Whether the design fits the target price range

-

Which materials drive costs up

-

Where structural simplifications can save money

Compared to correcting mistakes after bulk production starts, sampling costs are minimal.

Key benefit: Sampling helps brands make smarter pricing and margin decisions before committing to mass production.

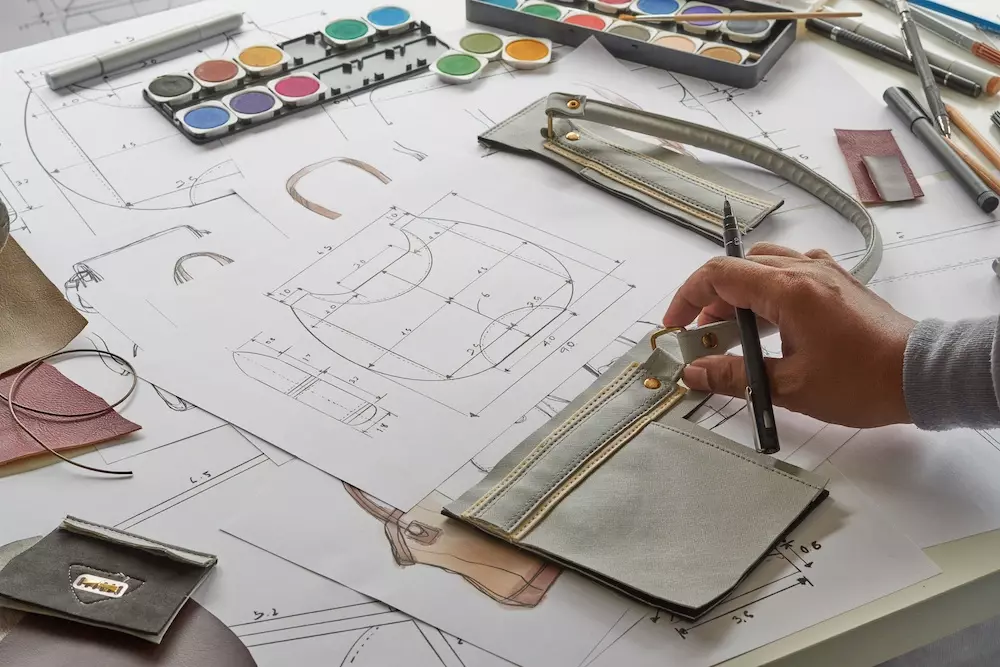

3. Production Feasibility: Turning Design Concepts into Manufacturable Products

Not every design that looks good on paper can be efficiently mass-produced.

Sampling tests:

-

Stitching complexity

-

Structural stability

-

Hardware installation feasibility

-

Assembly efficiency

From a factory standpoint, this step identifies potential issues that could slow down production or compromise quality at scale.

Key benefit: Sampling ensures the bag design is technically and operationally feasible for bulk manufacturing.

4. Approval Process: Eliminating Expectation Gaps Before Mass Production

Sampling creates a physical reference point that eliminates misunderstandings.

Through the approval process, brands can verify:

-

Size and proportions

-

Color accuracy and texture

-

Functional details (zippers, pockets, straps)

-

Overall craftsmanship

Once a sample is approved, it becomes the benchmark for mass production, reducing disputes and revision requests later.

Key benefit: Approved samples align expectations and serve as the final production standard.

5. Cost–Benefit Analysis: Sampling vs. Skipping Sampling

Skipping sampling may appear to save time and money, but it often results in:

-

Product inconsistencies

-

High defect rates

-

Rework or rejected batches

-

Delayed deliveries

Sampling, on the other hand:

-

Identifies risks early

-

Reduces error rates during mass production

-

Protects brand reputation

-

Improves long-term supplier efficiency

From a cost-efficiency perspective, sampling significantly lowers total production risk.

Key benefit: Sampling delivers long-term savings and stable quality for bulk orders.

Final Thoughts: Why Reliable Manufacturers Emphasize Sampling

From HerminFashion’s factory perspective, sampling is not just about approval—it is about responsibility and partnership.

By investing in a structured sampling process, brands gain:

-

Better cost control

-

Clearer production timelines

-

Higher product consistency

-

Stronger supplier collaboration

For custom bag orders, sampling is the foundation of successful mass production—not an extra step, but a necessary one.